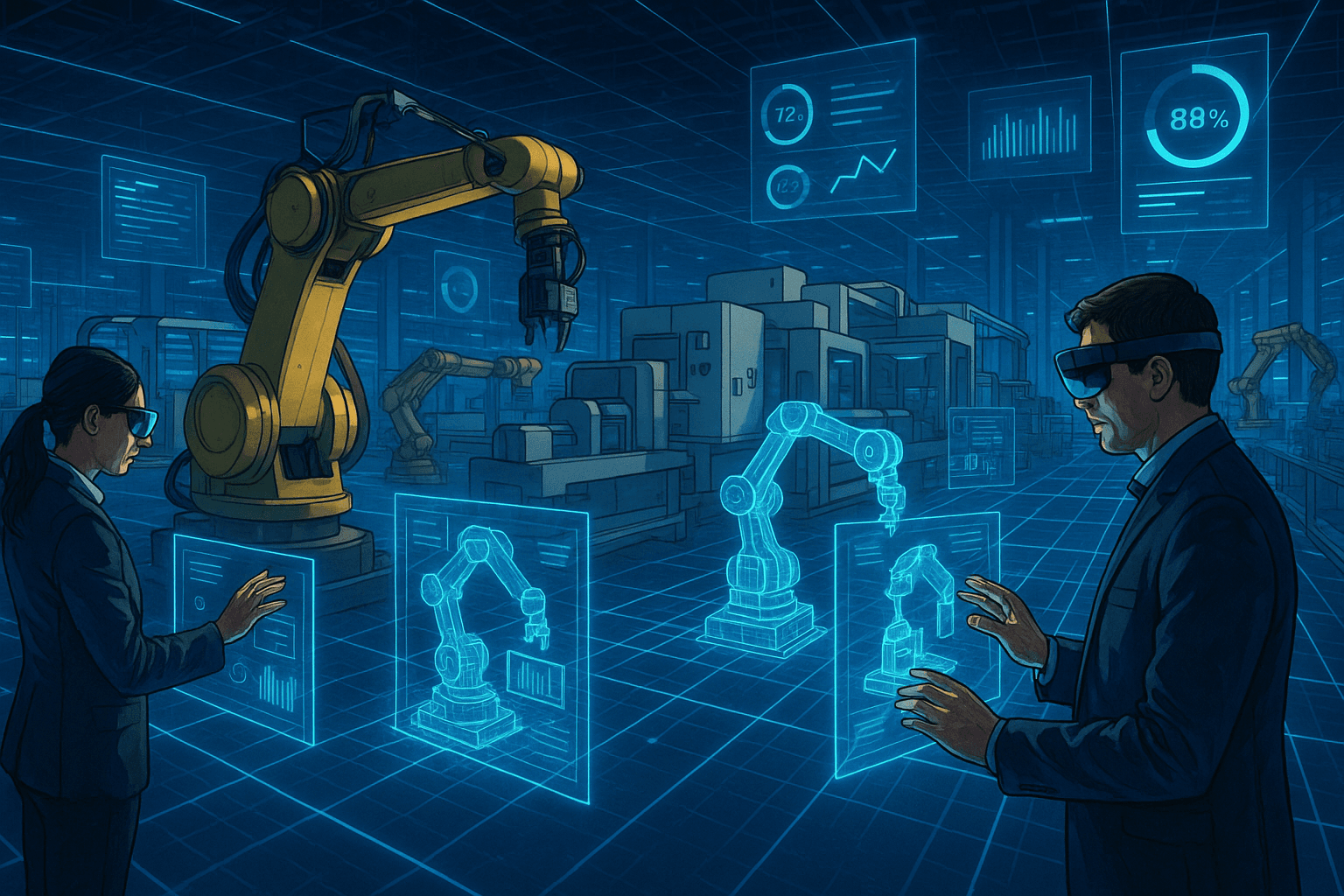

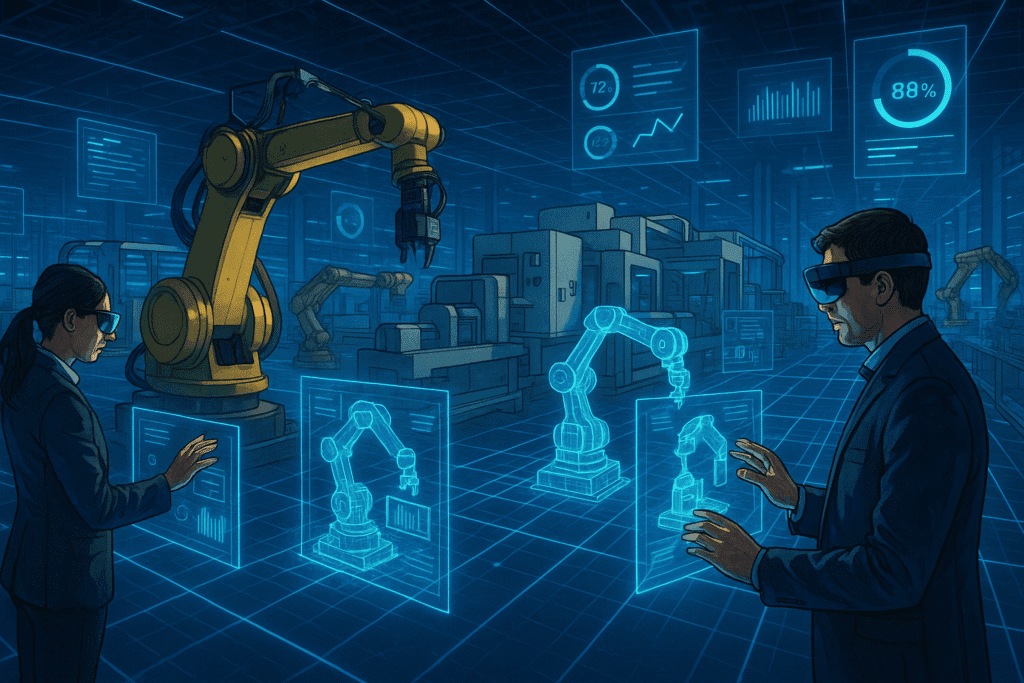

In simple terms, a digital twin is a live virtual copy of something real—like a machine, factory or power plant. It’s constantly updated with live data so changes in the physical world reflect in the virtual world instantly. This lets engineers simulate, monitor, and improve things without touching the real asset.

Over time, digital twin technology has evolved hand-in-hand with the rise of industrial IoT (IIoT), AI‑driven predictive analytics, and real-time simulation tools. As sensors proliferated, digital replicas became richer and more accurate. Artificial intelligence added predictive insight, while powerful simulation engines created immersive environments—all converging into what we now call the Industrial Metaverse.

Evolution: From IoT to AI and Real‑Time Simulation

IoT / IIoT Foundation

The explosion of IoT and IIoT devices (now numbering in the billions) allowed physical systems to stream sensor data—temperature, vibration, speed, orientation—into digital models in real time.

AI & Predictive Analytics

With AI layered on top, that real-time data becomes powerful predictive analytics—flagging anomalies or maintenance needs before a machine fails.

Real‑Time Simulation & Spatial Computing

Modern simulation platforms—like NVIDIA Omniverse—render virtual factories and systems in full 3D. They allow immersive interaction, VR/AR visualization, and scenario testing long before physical deployment.

Pillar of the Industrial Metaverse

Digital twins are the foundation layer of the industrial metaverse, enabling:

- Smart manufacturing operations: Real-time control loops powered by IIoT and AI let digital twins drive automated adjustments and optimization

- Immersive simulations and spatial design: Visualize an entire factory in 3D and test layouts before building.

- Predictive maintenance and analytics: Monitor digital twins of machines to schedule maintenance before failure occurs.

- Remote AR/VR collaboration: Teams across the globe can simultaneously work inside a shared virtual space representing a real factory or plant.

Real‑World Industry Examples

Manufacturing: BMW & Siemens

BMW used NVIDIA Omniverse to build digital twins of whole factories (including people and equipment) to simulate production lines and detect design issues before construction—saving time, money, and rework. Siemens’ smart‑factory in Nanjing used digital twins to double capacity and improve productivity by ~20 %.

Energy: Akselos & GE

Akselos builds structural digital twins of energy infrastructure to monitor stress, reduce downtime, and extend lifespan of power stations and pipelines. GE Digital’s Proficy platform manages digital twins for power grids, saving maintenance costs while improving uptime.

Aerospace: Airbus & Rolls‑Royce

Airbus uses living digital replicas throughout the product lifecycle—from design to in-service operations—enabling smarter decision-making using AI and simulation airbus.com. Rolls‑Royce uses digital twins to monitor engine health in flight and schedule predictive maintenance to avoid costly downtimes.

Construction & Smart Cities

Construction firms like Komatsu use digital twins to monitor real-time building performance and predict safety or process bottlenecks in advance. Smart‑city initiatives (e.g. city‑scale virtual models) use digital twins to help plan urban growth and energy use efficiently.

Benefits of Industrial Metaverse Enabled by Digital Twins

- Efficiency: Virtual testing accelerates design and deployment—errors are resolved before physical build.

- Cost savings: Reduces unplanned downtime (via predictive maintenance), cuts rework, and lowers capital and operational costs.

- Sustainability: Fewer physical prototypes, less waste, optimized energy usage in buildings and plants.

- Remote collaboration: Global teams collaborate virtually in real-time shared spaces.

- Scalable learning & AI: Simulations and synthetic data train AI for robotics and automation faster.

Challenges & Limitations

- Data integration: Connecting silos—design, production, maintenance—into a unified digital thread is complex and labor-intensive.

- Cybersecurity: The interconnected nature of digital twins increases attack surface—protecting them is critical.

- Scalability: Simulating everything—from micro‑components to full factories—requires massive compute; edge/ cloud balance is vital.

- Interoperability: Different platforms, simulation formats, and vendor locks hinder seamless collaboration and reuse.

Digital Twins vs Traditional Simulation Models

| Feature | Traditional Simulation Models | Digital Twin Technology |

|---|---|---|

| Data update frequency | Typically static, periodic | Real-time live data |

| Fidelity | Limited to predefined scenarios | Dynamic, continuously evolving model |

| Scope | Single process or component | Entire asset lifecycle or entire facility |

| Interactivity | Batch-run simulations only | Immersive VR/AR environments and shared spaces |

| Predictive capability | What‑if analysis only | AI‑driven predictive analytics and maintenance |

Digital twins go beyond traditional offline simulations—they mirror reality continuously and adapt as the physical asset evolves.

🔮 Future Trends & Emerging Technologies

AI‑Enhanced Digital Twins

Generative AI can help navigate massive models, suggest design optimizations, and enable data‑driven improvements across facilities.

Blockchain & Digital Trust

Blockchain can secure digital twinning by enabling immutable audit trails, rights management, and cross‑organization interoperability in the industrial metaverse.

Full VR/AR Industrial Metaverse

With XR devices, operators and engineers (the so‑called meta‑operators) will inhabit fully immersive industrial environments, combining digital twins, IoT, edge computing, and spatial tools into seamless workflows.

FAQ

Q: What exactly is a digital twin?

A: A digital twin is a live virtual replica of a physical object, system, or process that continuously receives data from its real-world counterpart, allowing monitoring, simulation, and optimization in real time.

Q: How does predictive maintenance work with digital twins?

A: Sensors stream operational data to the digital twin, AI analyzes it for anomalies or wear patterns, and alerts are issued before failures—enabling maintenance only when needed.

Q: How do digital twins support smart manufacturing?

A: They model entire production lines in real time, enabling AI-driven control loops, logistics forecasting, defect detection, and layout planning without halting operations.

Q: What are the main obstacles to adoption?

A: Enterprises face challenges in integrating siloed data, ensuring cybersecurity, scaling compute infrastructure, and ensuring interoperability across platforms.

Q: Can small firms adopt this technology?

A: Yes—many modular digital twin solutions are accessible via cloud or edge platforms, and even mid-sized firms can start with single-line or machine twins before scaling.